Environmental accountability in 2026 and beyond begins within semiconductor fabs and extends to the daily habits of every team member. Winbond’s Green Manufacturing Code anchors this shift, integrating decarbonisation principles across manufacturing, product design, and employee culture. Rather than viewing sustainability as a separate initiative, Winbond treats it as a structural foundation, one that influences decisions from technology investment to packaging choices and from product innovation to employee engagement.

Sustainability engineered into the fab

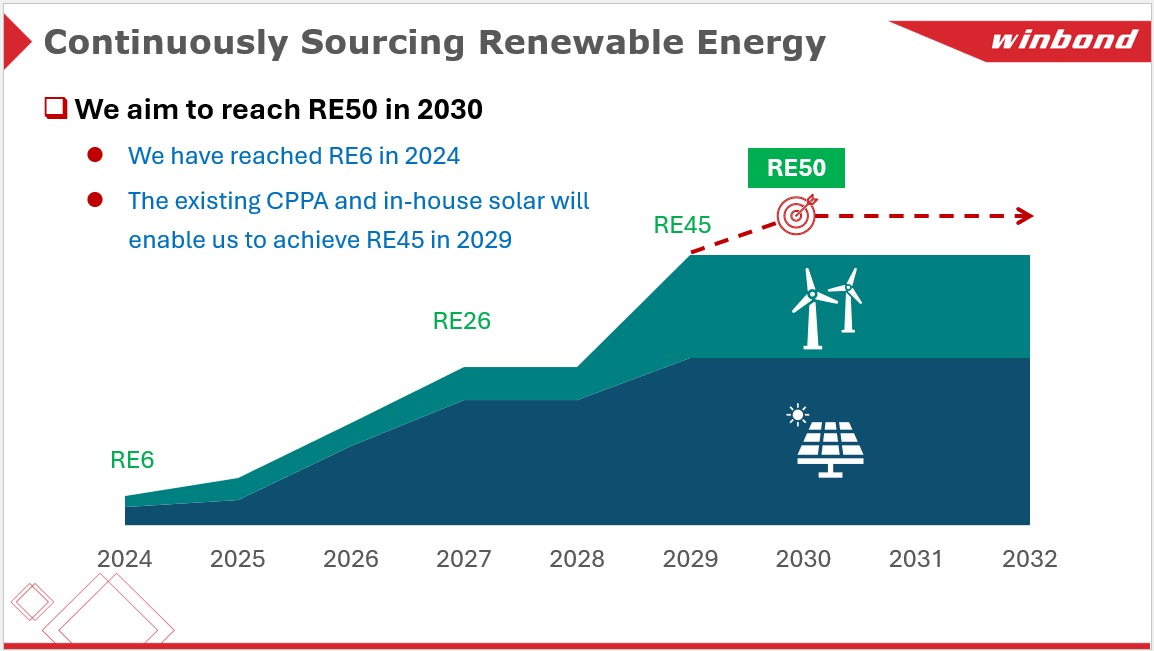

Advanced 12-inch fabs in Kaohsiung and the Central Taiwan Science Park (CTSP) embody a philosophy of combining smart and green manufacturing. CTSP, operational since 2022, has become a showcase for decarbonised operations. By 2024, it had achieved a 60% reduction in carbon emissions compared with 2021 and reached 90% electricity from renewables. Between 2022 and 2024, agreements totalling 27MW of solar and 12.84MW of wind energy were signed, with renewables expected to account for 8–10% of electricity use by 2025 and 50% by 2030.

That roadmap follows a clear trajectory: RE6 was achieved in 2024, RE45 is targeted for 2029, and RE50 by 2030. Across both fabs, Winbond applies standards including ISO 14064 for greenhouse gases, ISO 14067 for carbon footprinting, ISO 14046 for water footprinting, and ISO 50001 for energy management. Both sites are also ISO 46001 certified for water efficiency, with 2024 recycling rates reaching 81.9% overall and 89.3% for process water. These certifications ensure that sustainability is not just a corporate claim but a verified process.

From compliance to resilience

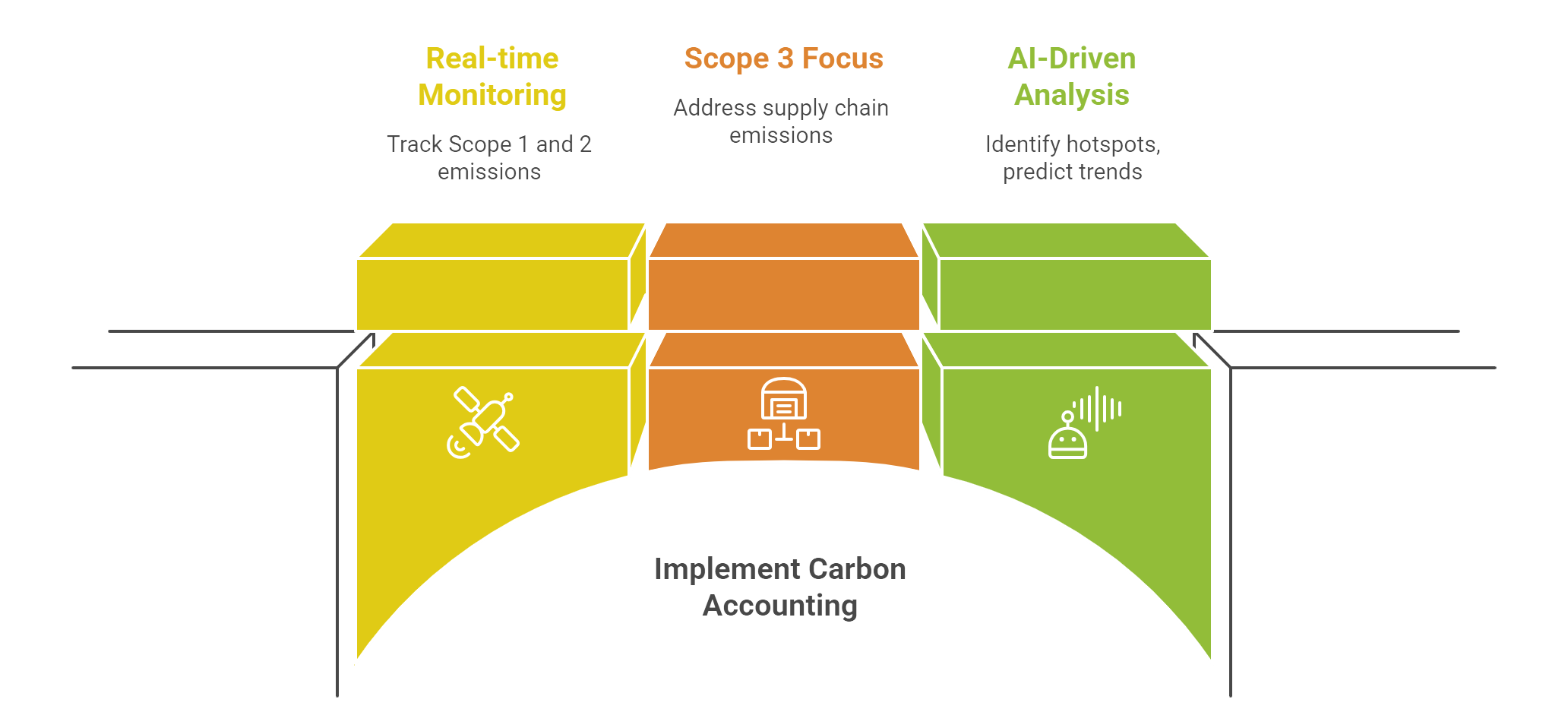

As carbon pricing and reporting frameworks tighten, manufacturers are reframing compliance as a driver of resilience. Real-time monitoring of Scope 1 and 2 emissions has become non-negotiable, while Scope 3 supply chain emissions, the most complex category, are gaining focus. Proprietary carbon accounting systems aligned with ISO 14064-1 and ISO 14067 use AI and big data to identify hotspots, predict emissions trends, and guide reduction measures.

The result is a model where product development is informed from the outset by environmental metrics, ensuring that solutions are not only technically advanced but also optimised for lower lifecycle impact.

Product innovation with sustainability built in

Customers across automotive, industrial, consumer, and computing markets are demanding evidence of sustainability in the components they use. Memory suppliers are responding with innovations such as:

- 1.2V Serial NOR Flash, which cuts power consumption by 50% compared with 1.8V devices.

- 1.2V HYPERRAM™, consuming around 33% less power than 1.8V devices.

- LPDDR4/4X, the 50% reduction in package size from 200BGA to 100BGA leads to a proportional decrease in packaging-related carbon emissions.

- CUBE memory, providing ultra-low power options for edge AI applications.

- Products manufactured using renewable energy, shipping since 2024 with around 60% lower carbon emissions than standard equivalents.

This product-led approach positions suppliers as partners, enabling system-wide sustainability improvements. Customers required to disclose carbon metrics increasingly rely on verified product footprints to strengthen their own reporting.

The role of digitalisation

Digitalisation is central to embedding sustainability. Carbon accounting has shifted from after-the-fact reporting to a data-driven, real-time process. Supplier input is verified, reporting frequencies are standardised, and carbon inventories are integrated into ERP and production systems. This improves transparency and traceability, while helping customers with their own disclosures.

At the facility level, automation and upgraded equipment reduce energy consumption at the source. Smart monitoring enables predictive adjustments, ensuring that no kilowatt-hour is wasted. Efficiency gains and sustainability goals are aligned rather than treated as competing priorities.

A cultural shift: employees as partners in decarbonisation

Technology and infrastructure alone are not enough. Companies are embedding environmental values into employee culture, recognising that cultural change is a prerequisite for progress. At Winbond, initiatives have brought together thousands of employees and their families for clean-up activities, removing hundreds of kilograms of waste from rivers, wetlands, and beaches. Wellbeing programmes also link individual health with ecological stewardship, creating a direct connection between personal habits and environmental outcomes.

Biodiversity projects extend this further. A 30-year afforestation project at the Kaohsiung fab, along with adoption of forest lands in Tainan and Chiayi, has resulted in more than 40,000 trees planted and an estimated carbon sink potential of 10,000 tons of CO₂ over three decades. These projects reflect a broader recognition that corporate responsibility extends beyond operations into long-term ecological stewardship.

Recognition and accountability

Progress is increasingly validated by third parties. Awards such as the National Sustainable Development Award, ECOVADIS Gold for supply chain sustainability, and inclusion in the S&P Global Sustainability Yearbook 2025 provide external confirmation. Independent verification of ESG reporting by BSI Taiwan adds further credibility. For customers and investors, these achievements show how sustainability performance is becoming intertwined with innovation and governance.

Looking toward 2026 and beyond

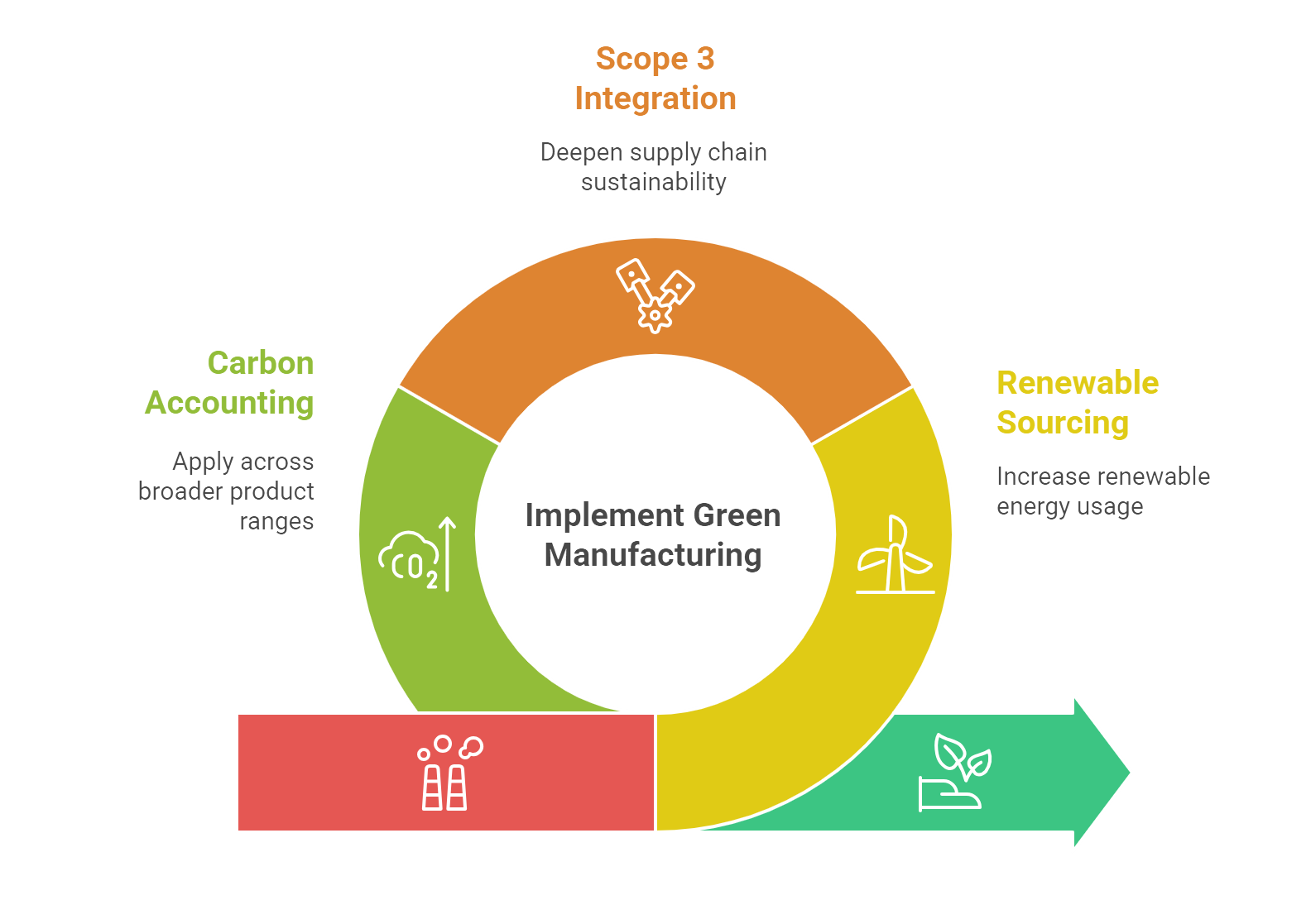

By 2026, green manufacturing codes and frameworks will not just be internal roadmaps but external markers of what sustainable semiconductor production looks like in practice. Renewable sourcing, lifecycle carbon tracking, employee engagement, and digital carbon accounting are emerging as key pillars of competitiveness.

The next phase will see companies expanding renewable sourcing, deepening Scope 3 integration, and applying carbon accounting across broader product ranges. With semiconductors central to mobility, healthcare, smart cities, and industrial automation, scrutiny of environmental footprints will only intensify.

Examples such as Winbond’s Green Manufacturing Code show how measurable progress toward net-zero can be achieved when sustainability is treated as a fundamental code rather than an optional add-on. The message for the wider industry is clear: in the years ahead, commitments will be judged by the discipline of everyday practice, not aspirational targets.

Conclusion

Net-zero in semiconductors cannot be achieved overnight, nor can it be addressed by a single department. It requires a system-wide approach — linking technical decision-making, cultural change, and governance into a coherent framework. The experiences of leading manufacturers demonstrate how this can be achieved: practical, measurable, and deeply integrated into operations.

Beyond 2026, such an approach will not be optional. It will define competitiveness, resilience, and reputation across the semiconductor industry.

English

English