The growth in the number of processor-based Electronic Control Units (ECUs) in cars is a familiar trend. Of equal significance to automotive system architects is the concurrent growth in the code footprint of new and developing applications in the car, a result in part of the increasing implementation of driver assistance and autonomous driving features, first in premium models, and rapidly filtering down to mid-range and even budget vehicles.

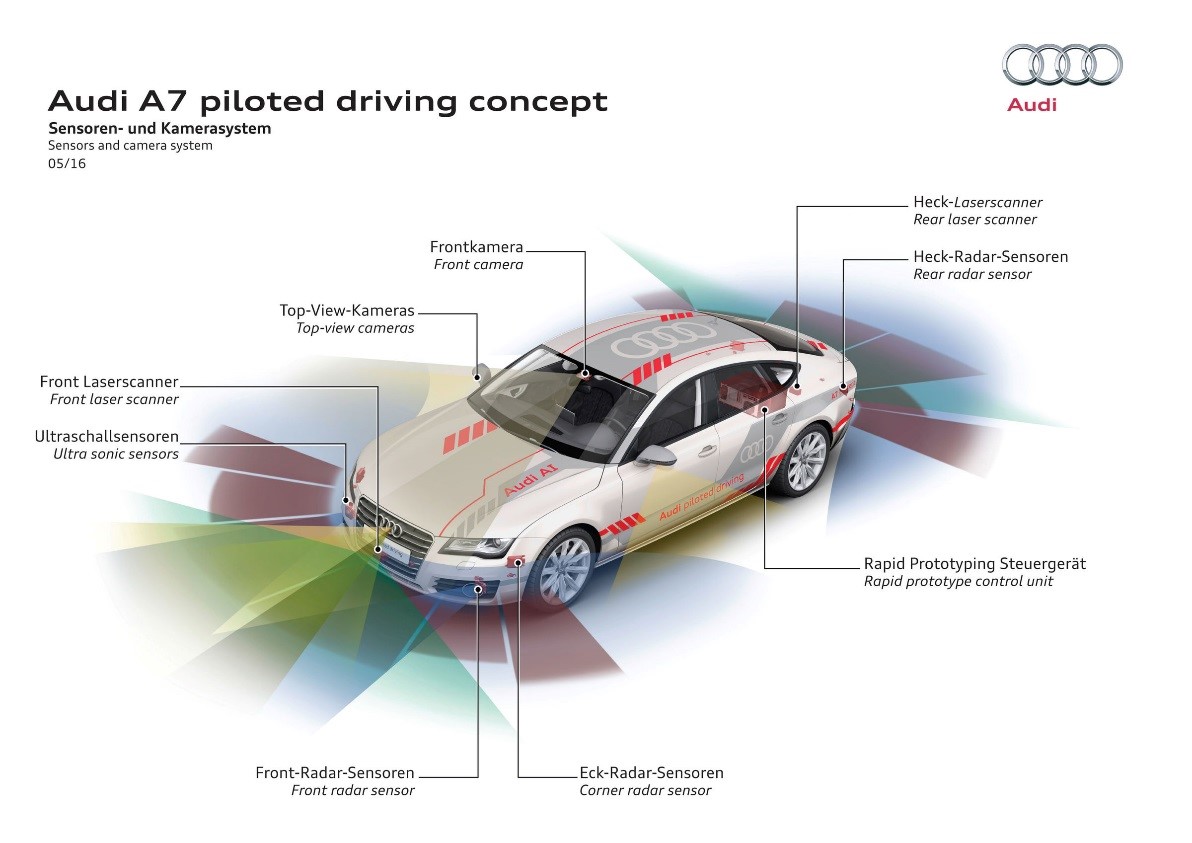

Early features of Advanced Driver Assistance Systems (ADAS) such as collision avoidance could typically be implemented in code of <256Mb. New car models under development today feature more sophisticated forms of driver assistance which rely on ranging and detection technologies such as radar and LiDAR, and which operate through an array of sensors (see Figure 1). The applications supported by these advanced sensor systems, such as highway auto-pilot and Lane Keep Assist, are producing steep rises in code size – the ECU in the front camera, for instance, is expected in cars under development today to be executing code of 1-2Gb in size.

This is prompting automotive system architects to re-evaluate their options for non-volatile code storage in the ECU. The scaling argument for considering a migration from discrete SPI NOR Flash memory – the conventional choice for code storage because of its high reliability, high data integrity and long data retention – to Serial NAND Flash has been fairly well aired in electronics engineering publications and at technical conferences.

Fig. 1: Audi’s ‘piloted driving concept’ for its A7 model, showing the array of sensors in new car designs. (Image credit: AUDI AG)

To recap, the structure of NOR Flash means that it occupies a larger die area per stored bit than NAND Flash: a Serial NAND Flash cell has an area of 4F2 compared to NOR Flash’s 10F2. Die area correlates to the cost of the packaged part, but not in a completely linear fashion: at densities of <512Mb, the proportion of the total die area occupied by control logic and the interface is relatively high, so the lower cost-per-bit of NAND storage cells has a smaller impact on total cost, favoring the use of SPI NOR Flash.

At densities of 512Mb and higher, the memory cells take up most of the die area, and so the smaller cell size of NAND Flash means that the total cost of the device is smaller than an SPI NOR Flash device with the same memory capacity.

For storage of a large body of automotive software, such as the front camera’s 1-2Gb of code, a Serial NAND Flash device, at around half the cost of the equivalent SPI NOR part, becomes worth considering.

But another factor seems to be proving decisive in the minds of many automotive system architects: the need to support over-the-air software updates. And here, the far superior Write throughput of the latest Serial NAND Flash technology gives it a strong advantage over SPI NOR Flash.

Protection against new security threats

Over-the-air (OTA) updating of system firmware is rapidly becoming a must-have capability in the next generation of passenger cars. This is for two main reasons. First, the increasing adoption of driver assistance and autonomous driving functions makes the car a better target than ever before for malicious cyber attack. If by design the car can be piloted by software, the possibility exists for the software to be hacked and altered so as to direct the car to operate dangerously in autonomous mode. The quickest way to apply a security patch to hacked firmware in the car is via an over-the-air update.

The second reason for the adoption of OTA updating is cost and convenience: if an update is delivered and applied automatically while the car is on the owner’s driveway, it saves the owner the time and trouble of taking the car to a service center, and it saves the cost to the manufacturer of contracting with service centers to apply updates. And if OTA updates are basically free of cost to the car manufacturer, they can be delivered much more frequently than in the past, enabling car makers to improve the value of their products by continually refreshing and upgrading the software features of the car.

The automotive market is already fully committed to supporting OTA updating in new models. As long ago as 2017, a Bosch spokesperson was saying, ‘in a few years from now, automatic software updates will be possible in every new car’. Continental has also publicly declared its commitment to implementing in its ECUs the technology required to support OTA updating.

The crucial parameters: Erase and Program speed

If OTA updating is to operate effectively and to be accepted by car users, it has to be secure, reliable – and crucially, quick. Speed is of the essence for the sake of the user – the car cannot be used while the update process is in progress – and for operational effectiveness: the shorter the update process, the less likely it is to be disrupted or disabled by a breakdown in the car’s wireless connection to the car manufacturer’s data center.

And for fast software updating, new Serial NAND Flash products have a clear advantage over the fastest SPI NOR Flash. Fast Write is an inherent feature of Serial NAND Flash – it is true, even without the application of proprietary acceleration techniques.

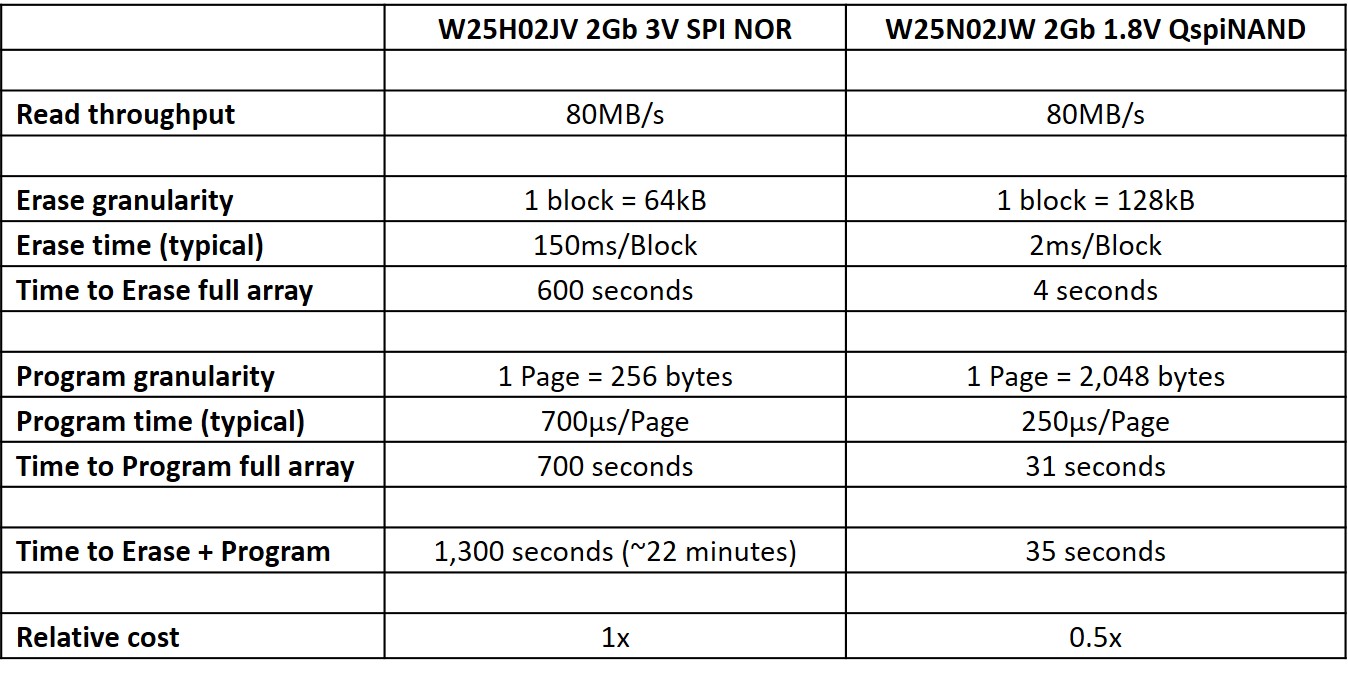

Figure 2 shows the comparison in update duration between Winbond’s W25H02JV, a 2Gb SPI NOR Flash part, and the 1.8V W25N02JW, a 2Gb Serial NAND (or QspiNAND – the terms are interchangeable) device. An OTA updating operation is performed in two stages: first, the old code is erased from memory, and then the new code is written to it. The speed of the Erase process in Serial NAND is around 100 times faster than that of SPI NOR. The program speed of Winbond’s high-performance QspiNAND (Quad SPI NAND) Flash is around five times faster than the fastest SPI NOR Flash on the market. Overall, the Write throughput of Serial NAND Flash is over ten times faster than even the fastest SPI NOR Flash.

This means that the time to program a front camera’s 2Gb software stack is just 35s if it is stored in a monolithic W25N02JW device consisting of two W25N01JW dies in a stacked die configuration. It takes 22 minutes to store the same code in an SPI NOR Flash array based on the W25H02JV.

Fig. 2: Write speed comparison of SPI NOR and QspiNAND Flash devices. (Source: Winbond)

The erase and programming speed advantage provided by Winbond’s automotive-grade QspiNAND Flash requires no compromise in quality: fabricated on a proven and robust 46nm process, the Winbond Single-Level Cell (SLC) NAND Flash offers comparable data integrity and endurance specifications to SPI NOR Flash, to provide highly reliable performance in safety-critical automotive applications over a car’s entire operating lifetime.

The new question: boot speed

The speed of the OTA update process, then, encourages automotive manufacturers to adopt Serial NAND Flash, which offers high Write throughput, for large bodies of code of 512Mb and more.

But increases in code size have an impact on boot speed, as well as on programming speed. In ADAS systems such as the front camera, Flash memory is used in code-shadowing mode: on start-up, the code is downloaded from Flash to a type of DRAM such as LPDDR4. This download time is a key determinant of the total boot time, a crucial parameter which car manufacturers manage very carefully: the driver expects the car’s systems to be ready within seconds after pressing the Start button.

On this parameter, Winbond’s QspiNAND Flash products offer similar performance to standard SPI NOR Flash, as Figure 2 shows. With Read throughput of 80MB/s, an ECU’s 1Gb of code can be downloaded in 1.5s – an acceptable duration in the automotive context. If the ECU contains 2Gb of code, however, this download time rises to 3s, extending the vehicle’s total boot time further. Some car manufacturers might wish to reduce the duration of the download.

Here, the latest development in NAND Flash technology might be appropriate (see Figure 3): Winbond’s OctalNAND Flash memory offers the same cost-per-bit advantage over Octal NOR Flash as QspiNAND offers over SPI NOR, and gives the same superiority in Write throughput. But OctalNAND, benefiting from an x8 interface similar to DRAM, offers much higher Read throughput of 240MB/s. Using OctalNAND Flash, the entire 2Gb code can be downloaded in just 1s, fast enough for any car manufacturer’s boot time specification.

Fig. 3: OctalNAND Flash from Winbond provides for fast boot in automotive applications. (Image credit: Winbond)

The industry-standard 8mm x 6mm BGA package of the W35N-JW OctalNAND parts is footprint-compatible with Serial NOR Flash products, and is fully pin-compatible with Xccela™ Flash and Octal Flash NOR products on the market today.

Cost, speed and production efficiency benefits

The use of QspiNAND Flash to store automotive code of 512Mb or larger offers cost savings over equivalent SPI NOR Flash devices of some 50% - a useful benefit in itself. But car manufacturers are now also finding that QspiNAND and OctalNAND also give dramatic reductions in Write time – crucial for the implementation of OTA updating.

On top of that, the faster Write time of QspiNAND also improves efficiency and throughput in the factory when writing large amounts of code to an ECU, giving automotive manufacturers yet another reason to evaluate the benefits of migration from the traditional choice of SPI NOR Flash for code storage in safety- and mission-critical applications.

by Anil Gupta, Technical Executive, Winbond Electronics Corporation America