Reducing Environmental Impact Through Energy Efficiency, Waste Management, and Renewable Energy Integration

As environmental awareness grows, businesses face significant pressure to adopt sustainable practices. Green manufacturing significantly contributes to this shift by minimising environmental impact through waste reduction, energy conservation, and efficient resource use. Winbond, the semiconductor memory manufacturer, has realised significant benefits through diverse and inventive ways of embedding sustainability into manufacturing processes. This article examines the essential areas companies need to focus on to demonstrate their commitment to green manufacturing and underscores the benefits of this approach.

Key Areas of Focus in Green Manufacturing

- Energy and Carbon Emissions Management

Energy Efficiency: Implementing energy management systems like ISO 50001 helps standardise processes and improve energy efficiency. For instance, Winbond's commitment to energy conservation is evident through its efforts to optimise equipment and processes, which have led to significant energy savings and reduced carbon emissions. The reduction target for energy and electricity consumption is 1% YOY reduction of electricity usage per unit product by 2030. Companies must focus on continuously improving energy performance, prioritising the procurement of energy-efficient products and integrating renewable energy sources.

- Water and Waste Management

Companies must focus on water conservation and waste minimisation to practice green manufacturing. Water should be recovered and reused as much as possible, like Winbond's Fabs recycled a total of 13.15 million cubic meters of water, resulting in a water recovery rate of 82.2% across the entire facility. It showcases how efficient water management reduces environmental impact.

Companies should also invest in stable water sources and infrastructure to manage shortages, as seen with Winbond’s 75,000-cubic-meter underground reservoir, ensuring continuous operations during water scarcity. Tracking water usage metrics can identify areas for improvement.

Waste minimisation is equally important. Companies should reduce waste by repurposing and recycling materials, turning liabilities into resources. In 2023, Winbond's waste output was approximately 13,595 metric tons, with an average waste output of about 0.531 kilograms per layer mask for 12-inch wafers; all hazardous industrial waste is processed by qualified domestic waste treatment facilities. The long-term goal for waste management is to achieve a waste recovery rate of 90% annually by 2030. Managing emissions and recycling programs help lessen the environmental impact. By integrating water conservation and waste minimisation, companies contribute to sustainability while maintaining operational efficiency.

Fig 1. Integrating Water and Waste Management.

- Air Pollution Control

Emission Reduction: Companies must adopt advanced technologies to reduce air pollution. Regular monitoring and upgrading of emission control systems are critical for maintaining air quality and complying with environmental regulations.

Winbond prioritizes air pollution prevention through source reduction and effective treatment. Process improvements minimize pollutant generation, while high-performance control equipment ensures emissions meet stringent government standards. Local scrubber equipment captures and treats hazardous emissions, achieving a 98% removal rate for VOCs in 2023. A real-time monitoring system ensures stable operations and compliance with environmental regulations. Winbond's commitment to air pollution control demonstrates its dedication to sustainable practices.

- Renewable Energy Investment

Companies should focus on reducing direct emissions and integrating renewable energy. As Winbond has done, promoting a net-zero culture engages the workforce in emission reduction by rethinking product and process design from a cradle-to-cradle perspective. Setting environmental targets, implementing data governance, and establishing carbon accounting systems are key to sustained progress.

Efforts should extend beyond individual sites to subsidiaries and branches. Winbond’s reduction of 2.28 million tCO2e emissions shows the value of collaboration across industries. Partnering with organisations like the Taiwan Semiconductor Industry Association (TSIA) and the World Semiconductor Council (WSC) can drive significant greenhouse gas reductions.

Investing in renewable energy is essential. Companies should transition from fossil fuels, as Winbond’s NT$955 million investment and commitment to 90% renewable energy at its CTSP (Central Taiwan Science Park) fab by 2030 demonstrate. Procuring wind and solar power ensures clean electricity and reduces environmental impact.

Nature-based carbon removal strategies, such as afforestation and blue carbon projects, provide additional ways to offset emissions. Winbond’s 30-year afforestation plan shows how businesses can integrate biodiversity conservation into sustainability. Participation in carbon trading and long-term carbon removal projects helps meet net-zero targets and supports climate change mitigation.

Companies can lead sustainable manufacturing efforts and support global environmental goals by reducing emissions, using renewable energy, and exploring carbon removal.

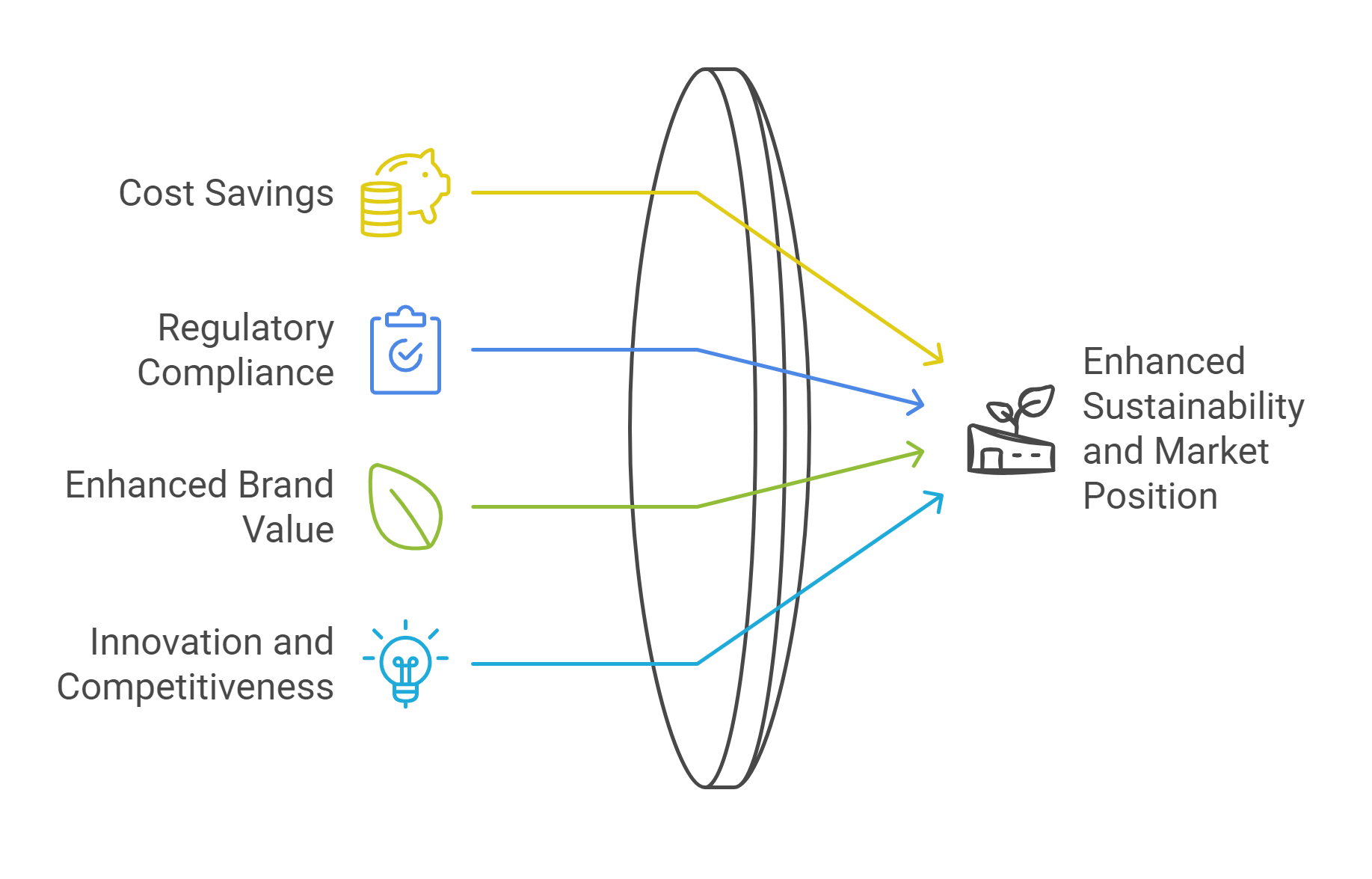

The Benefits of Green Manufacturing

Fig 2. By reducing environmental footprint through energy management, carbon reduction, water and waste management, air pollution control, and renewable energy investment, while also enhancing brand value, competitiveness, and sustainability

Cost Savings: Reducing energy consumption and waste directly translates into lower operational costs. Efficient resource use means companies can achieve more with less, leading to long-term cost savings.

Regulatory Compliance: As governments worldwide tighten environmental regulations, green manufacturing helps companies stay compliant, avoiding potential fines and sanctions. Adhering to international standards like ISO 46001, ISO 14001 and ISO 50001 ensures compliance and enhances the company’s reputation.

Enhanced Brand Value: Consumers increasingly favour companies that commit to sustainability. Green manufacturing helps build a positive brand image and attract environmentally conscious customers and investors.

Innovation and Competitiveness: Adopting green practices often spur innovation as companies seek new ways to reduce environmental impact. This can lead to developing new products, processes, and technologies that provide a competitive edge in the market.

Companies can significantly reduce their environmental footprint by focusing on energy and carbon emissions management, water and waste management, air pollution control, and renewable energy investment. The benefits of such practices extend beyond environmental impact, offering cost savings, regulatory compliance, enhanced brand value, and increased competitiveness. Companies like Winbond exemplify how integrating green manufacturing into business operations can lead to sustainable success, positioning them as leaders in the global effort to achieve environmental sustainability.

English

English