According to industry analysts, the global Internet of Things (IoT) market size is projected to grow from $714.48 billion in 2024 to $4,062.34 billion by 2032. With a CAGR of 24.3%, this market growth is driven by advancements in technology that continue to enhance miniaturization, low power consumption, and performance. As devices shrink in size, they incorporate more features and functionalities than ever before, enabling new applications that were previously impractical.

One of the key drivers behind this trend is NOR Flash memory, which powers these devices. This is particularly evident in industrial factory automation and smart home control applications, where integration, energy efficiency, and performance are crucial. These markets also demand resilience to high temperatures. In industrial environments, smart devices often operate in locations with significant heat generation, such as factory floors, oil refineries, or automobiles, necessitating effective performance under harsh conditions.

While the environmental demands may be less stringent, the IoT wearable sector faces its own challenges with heat management. Manufacturers frequently stack memory atop hot CPUs or MCUs to reduce device size or introduce new functionalities within the existing footprint.

Spans Many Markets Segments

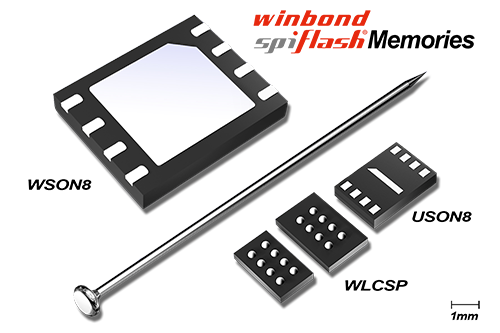

Winbond’s W25QxxRV NOR Flash memory is currently available in densities ranging from 1Mb to 32Mb, with higher densities set to be launched soon. The RV family offers low power consumption, a compact form factor, and supports industrial temperatures up to 105°C, making it suitable for various markets and applications:

- Industrial: Designed to withstand harsh conditions such as high temperatures, vibrations, and exposure to chemicals, Winbond's NOR Flash is ideal for industrial automation systems and control units, supporting temperatures up to 105°C.

- Consumer: Offers low power consumption to extend battery life, and features a compact design suitable for lightweight portable gadgets.

- Automotive: Supports numerous electronic control units in vehicles, operating reliably under extreme temperatures and vibrations, and fitting into small, hard-to-reach spaces.

- Computing: Enhances battery life through low power consumption, allowing for extended operation without frequent recharging.

- Networking: Benefits routers and switches by reducing power consumption, managing thermal performance effectively, and lowering energy costs.

To address these challenges, Winbond continues to lead with innovation through its latest NOR Flash memory family, the W25QxxRV. This series represents a substantial leap in performance and efficiency compared to earlier NOR Flash generations. Utilizing newly updated 58nm technology and optimized flash array architecture, the W25QxxRV offers the following key advantages to customers:

- Support for industrial grade temperatures up to 105°C.

- 133MHz Fast Read Clock Frequency enhancing XiP (eXecute in Place). This represents a 20% improvement from Winbond’s prior generation.

- A 30% increase in normal read with support for 66MHz.

- Improved OTA firmware update performance.

- A 50% reduction in page programming time which delivers significant cost benefits to customers.

- A 25% reduction in Read Current contributes to battery life optimization.

- Support for a wider range of packages for space-constrained applications, enables more compact designs in markets such as consumer electronics where space is limited.

Backed By State-of-the-art Manufacturing

The W25QxxRV is manufactured in Winbond’s 12-inch wafer fab using the latest generation of Winbond’s 58nm technology. In addition to small-form-factor packaging, the W25QxxRV is suitable for space-constrained applications where the flash Known Good Die (KGD) or Wafer-Level Chip Scale Package (WLCSP) is combined with the System-on-Chip (SoC) in a System-in-Package configuration.

With read speeds improved from 104MHz to 133MHz, page programming time slashed by 50%, and active read current reduced by up to 20%, the system functions of the W25QxxRV have been significantly optimized. Execute-In-Place (XiP) of code operates at a higher frequency, enabling greater system responsiveness while consuming less energy. Moreover, faster programming accelerates factory throughput and reduces manufacturing costs. The short time required for Over-the-air (OTA) firmware updates ensures greater system availability and less downtime, resulting in a superior end-user experience.

The W25QxxRV supports all standard single/dual/quad/QPI commands and read modes for XiP and code shadowing to RAM. This device operates on a single 2.7V to 3.6V power supply with a power-down current as low as 1μA. Active read current is reduced from 12mA to 10mA at 104MHz. This family of flash products is organized into 64KB or 32KB blocks, further subdivided into small 4KB sectors, enhancing flexibility and storage efficiency for applications requiring code, data, and parameter storage in the same device. It also supports 66MHz Double Data Rate (DDR) operation, allowing the system to achieve high-speed read throughput equivalent to 133MHz Single Data Rate (SDR). The Read Command Bypass Mode supports faster memory access for true XIP operation by eliminating the command input cycle.

The Gold Standard in the NOR Flash Market

Due to its support for temperatures up to 105°C, low power consumption, and a wide range of package options, the W25QxxRV has emerged as the ideal choice for applications in industrial IoT, consumer electronics, computing, and networking, where reliability, efficiency, and durability are crucial. Its versatility also extends to emerging domains such as edge computing and AI applications, particularly in industrial and computing environments where high temperatures are prevalent, supporting high workloads driven by applications such as AI and HPC.

English

English